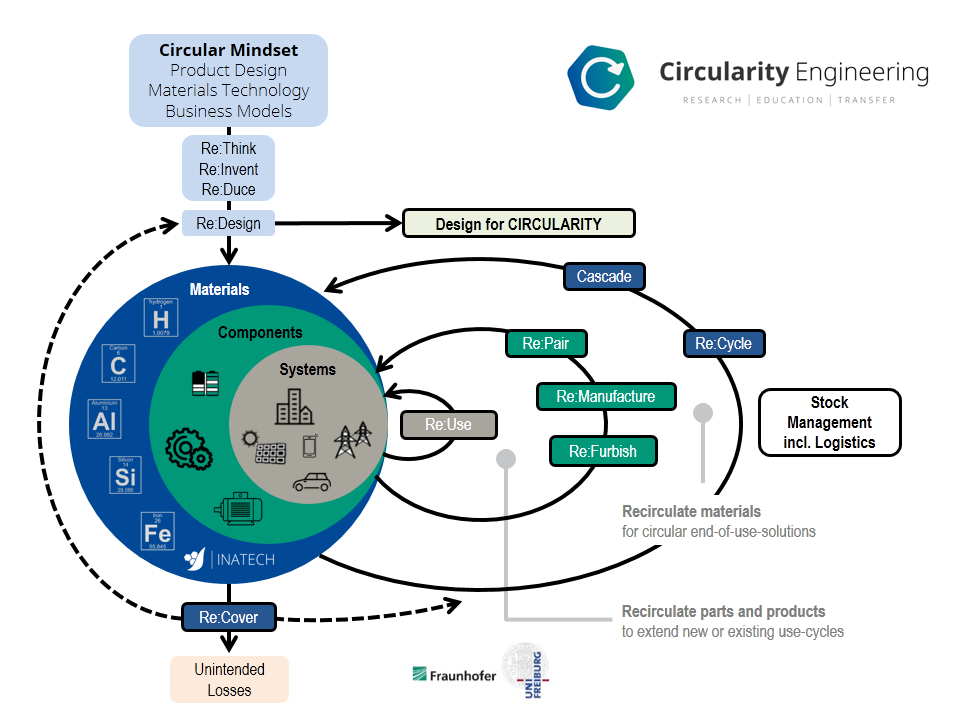

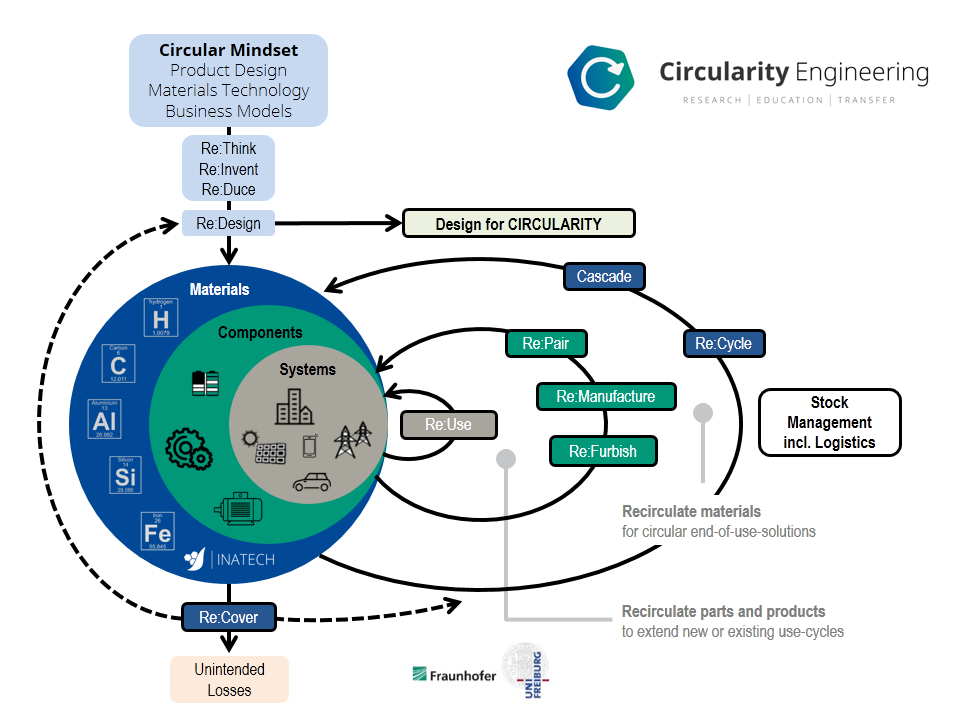

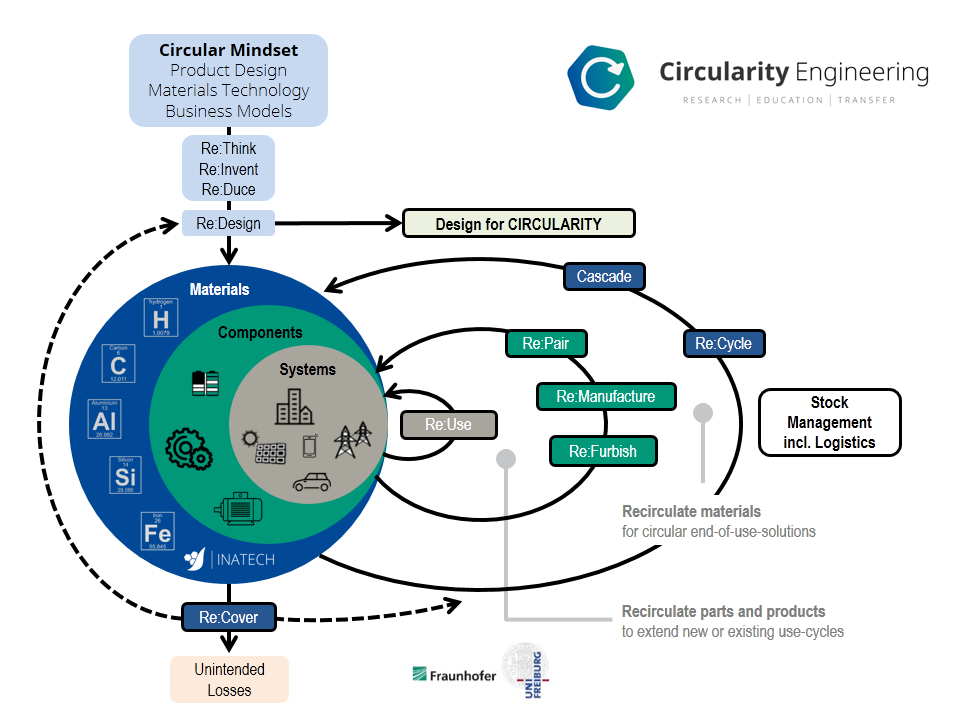

... designs engineering systems in such a way that they consist of circular, environmentally compatible and resilient products, components and materials.

Circularity engineering is an ab initio concept starting with the materials selection, product design, manufacturing and process selection and not, like the currently practiced circular economy, starting with the waste of linearly planned products and systems.

As a core element of a holistic resource transition, i.e. for material, energy and also human resources, Circularity Engineering is central part of INATECH's research and education agenda.

Anchoring ecological, social and health aspects in engineering processes: in the medium term, "Circularity Engineering" should become a core element of sustainable engineering science.

To this end, INATECH is developing the scientific basic principles for new engineering methods, processes and tools that can be integrated into all traditional engineering disciplines:

Selected projects in the field of Circularity Engineering

Bogachuk, D., van der Windt, P., Wagner, L., Martineau, D., Narbey, S., Verma, A., ... & Glunz, S. W. (2024). Remanufacturing perovskite solar cells and modules–a holistic case study. ACS Sustainable Resource Management, 1(3), 417-426. https://doi.org/10.1021/acssusresmgt.3c00042

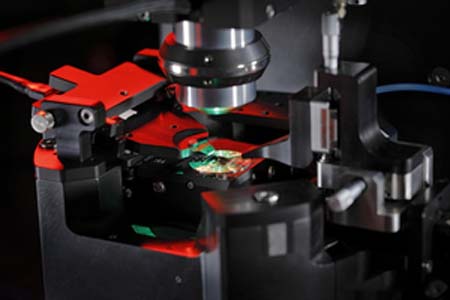

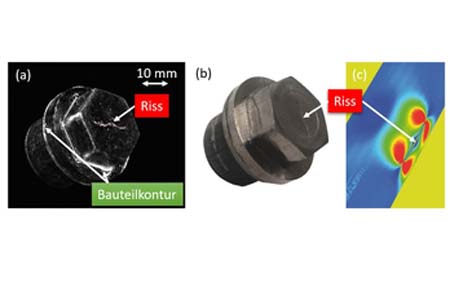

Ragupathi, B., & Balle, F. (2024). Characterization of glass-fiber reinforced thermoplastic composite after ultrasonic reconsolidation. European Journal of Materials, 4(1), 2313316. https://doi.org/10.1080/26889277.2024.2313316

Geist, H., & Balle, F. (2024). Remanufactured products, components, and their materials: A circularity engineering focused empirical status quo analysis. Sustainable Production and Consumption, 45, 525-537. https://doi.org/10.1016/j.spc.2024.02.003

Geist, H., & Balle, F. (2024). A circularity engineering focused empirical status quo analysis of automotive remanufacturing processes. Resources, Conservation and Recycling, 201, 107328. https://doi.org/10.1016/j.resconrec.2023.107328

Ragupathi, B., Bacher, M. F., & Balle, F. (2023). First efforts on recovery of thermoplastic composites at low temperatures by power ultrasonics. Cleaner Materials, 8, 100186. https://doi.org/10.1016/j.clema.2023.100186

Ragupathi, B., Bacher, M. F., & Balle, F. (2023). Separation and Reconsolidation of thermoplastic glass fiber composites by power ultrasonics. Resources, Conservation and Recycling, 198, 107122. https://doi.org/10.1016/j.resconrec.2023.107122

Oliveira, P. R., Virgen, G. P. G., Imbert, M., Beisel, S., May, M., Panzera, T. H., ... & Balle, F. (2023). Ultrasonically welded eco-friendly sandwich panels based on upcycled thermoplastic core: An eco-mechanical characterisation. Resources, Conservation & Recycling Advances, 20, 200187. https://doi.org/10.1016/j.rcradv.2023.200187

DIN SPEC 91472:2023-06: Remanufacturing (Reman) – Quality classification for circular processes. https://www.dinmedia.de/de/technische-regel/din-spec-91472/367509951

INATECH, Emmy-Noether-Str. 2,

D-79110 Freiburg

Germany

Tel.: +49 (0)761/203-54226

efm@inatech.uni-freiburg.de