Infrastructure

INATECH offers comprehensive facilities for engineering research into and development of sustainable technologies.

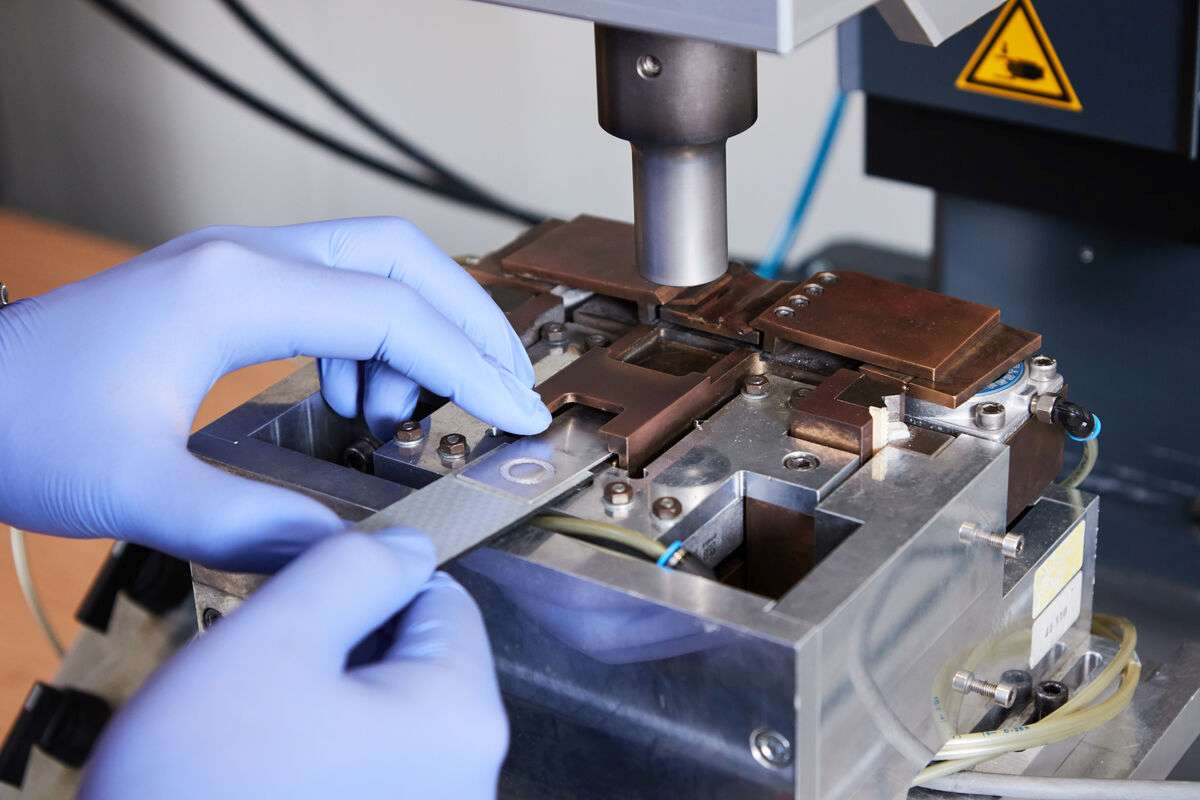

Characterization of monotonic and fatigue properties

Laboratory for materials testing and study of materials systems

Modern testing machines are used for disruptive material testing and characterization. They are of the type used in current research practices and state-of-the-art university education. They enable, for example, the exact calculation of material properties as of the local stability of joint connections. Monotonic isotherm tensile and pressure tests, cyclical tests (fatigue), quasi-static and cyclical bend tests are currently being carried out at ambient temperatures relevant to engineering applications.

Application

Characterization of material properties for metals, polymers and composites as well as multi-metal or hybrid composite materials.

Facilities

-

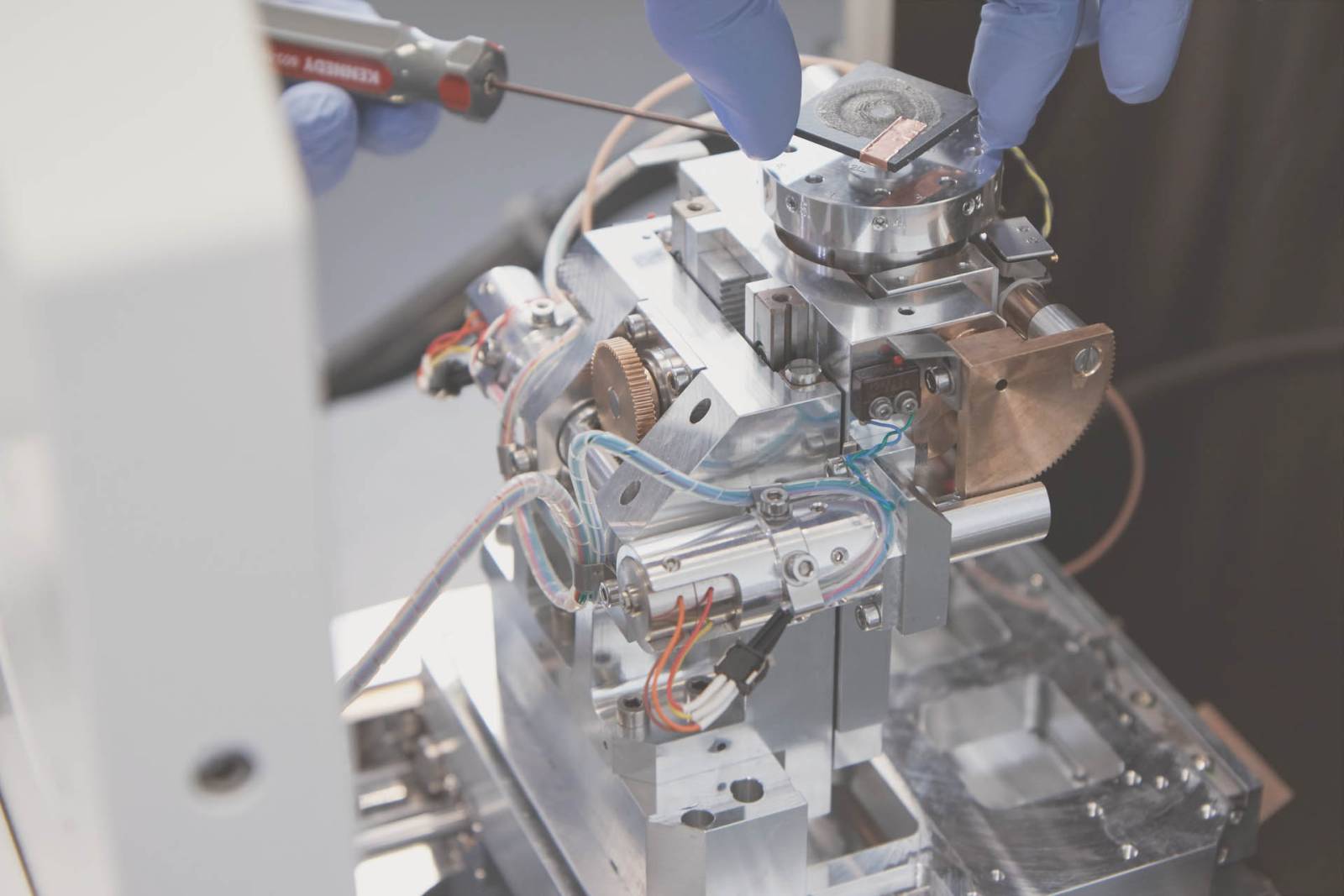

Servo hydraulic testing system ZwickRoell HC25

Maximum load 25 kN for tensile or compression. Cyclic tensile/compression testing or 3-point bending load with 100 Hz test frequency in maximum. - Monotonic tensile testing system ZwickRoell Z020

- Monotonic tensile testing system ZwickRoell Z100

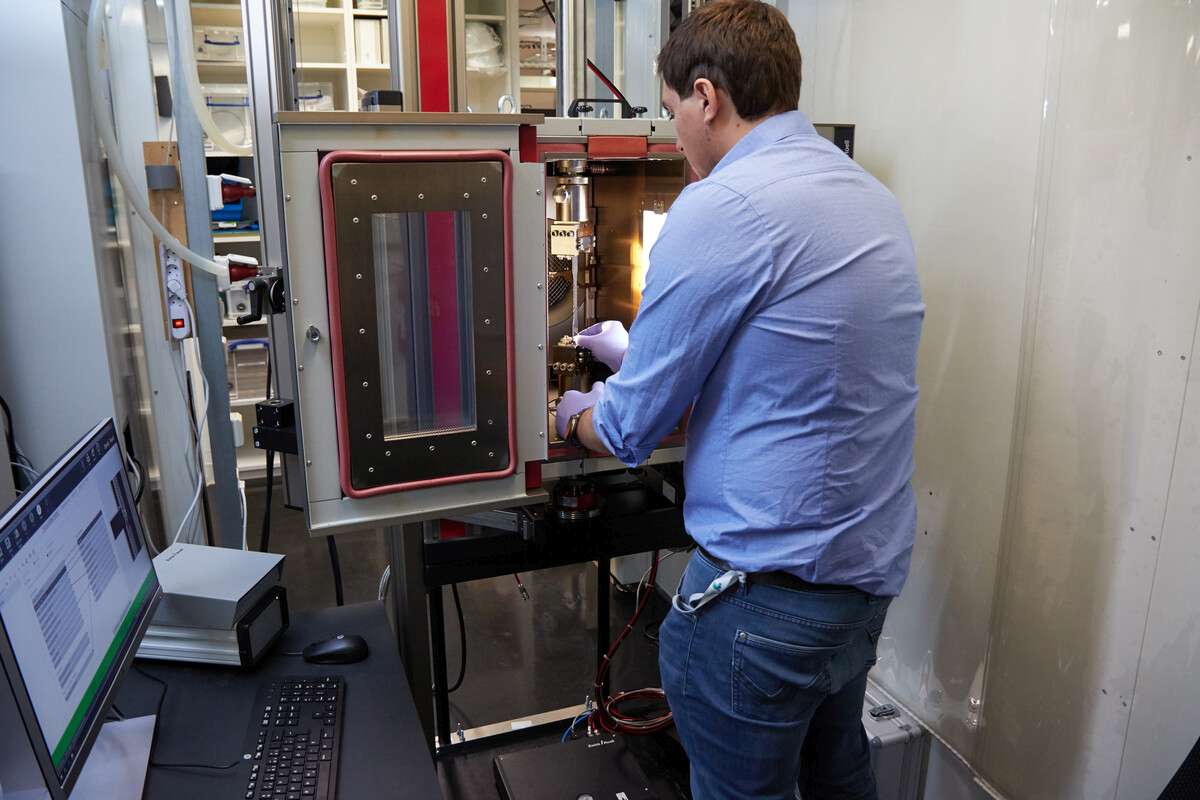

- Thermal chamber ZwickRoell 400x640

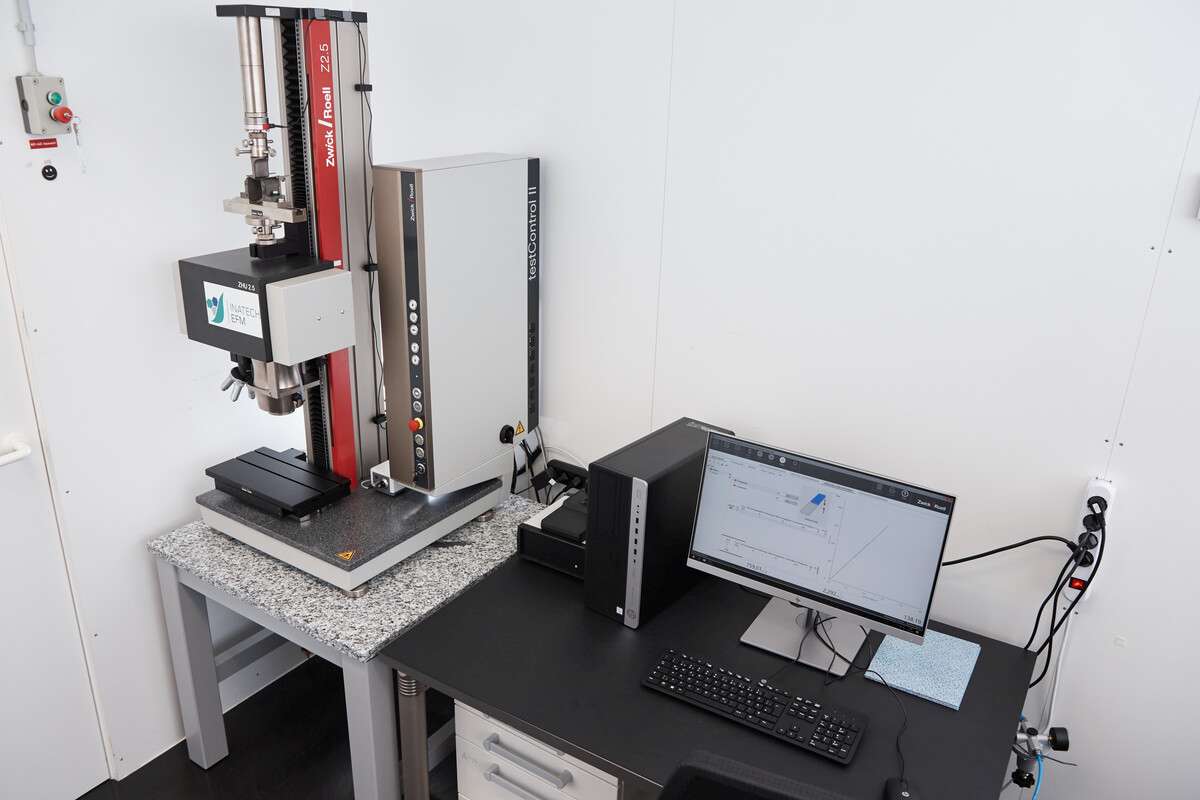

- Universal testing system ZwickRoell ZHU2,5 incl. instrumented hardness testing

- Pendulum impact tester ZwickRoell Hit50P

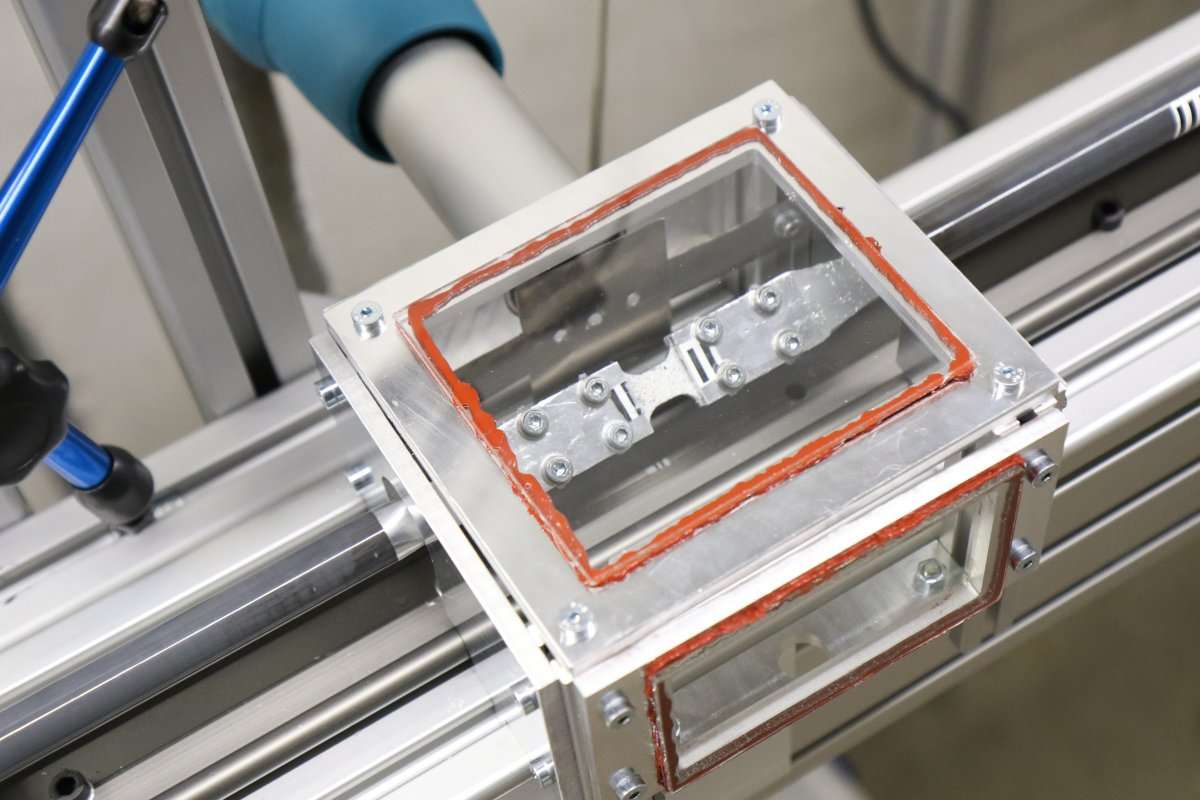

- Ultrasonic fatigue system (VHCF) for tensile/compressive loading.

- Ultrasonic fatigue system (VHCF) for 3-point bending stresses

- Face quenching test facility (Jominy test) Latzke

Maximum test load 20kN. VideoXtens extensometer with 0.15µm optical resolution. Pneumatic specimen grips for time-saving and eccentric testing of joints.

Maximum test load 100kN. Extensometers. Mechanical specimen grips

Temperature range -80°C to 250°C. Usable for test systems HC25, Z020 and Z100

Maximum load 2.5kN. Hardness tests according to Rockwell, Vickers, Brinell and Martens. 3-point bending tests in specially adapted upper test chamber.

Charpy impact tests with a working capacity of 50J maximum.

Dynamic tensile/compressive stress at 20 kHz. Maximum vibration amplitude up to 50 m. Stress ratio R = -1.

Dynamic 3-point bending stress at 20 kHz. Maximum vibration amplitude up to 57 m. Stress ratio R > 0.

Cooling device for standardized Jominy specimens and clamping device for hardness testing equipment to investigate hardness curves.