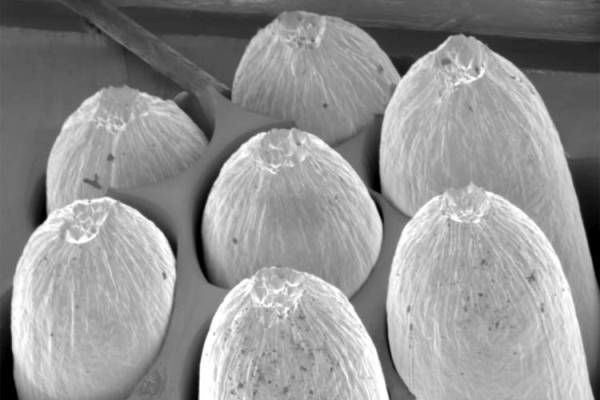

The pivotal “Ultra + X” research project covers all areas that use power ultrasonics for characterizing or producing mostly hybrid materials systems. Frequency oscillations of up to 20,000 Hz are used to join very different materials, particularly light metals (Al, Ti, steels) with polymerized fiber-composite materials (CFK, GFK), and also glass and ceramics. A long-term goal is the further development of power ultrasonics towards a sustainable technology that can join, separate and repair “at the push of a button”; in other words, technical metabolism. Moreover, the technology used for the patented, quick calculation of the shelf-life of fiber-composite materials, is also employed to deeply examine application-relevant issues on the robustness and durability of materials systems.